EXTRUSION CAST

LE FILM À BULLES « QUALITÉ FRANÇAISE »

CID Plastiques met à votre disposition ses compétences, son savoir-faire et son dynamisme.

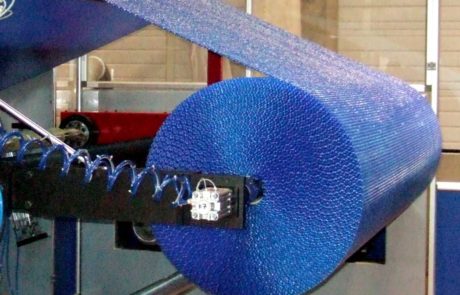

Spécialisé dans l’extrusion en filière plate (extrusion dite «cast» qui permet de produire des films à bulles de 60 à 550 μm), CID Plastiques fabrique des rouleaux de films à bulles à la fois pour son propre usage mais également pour la vente aux transformateurs de film piscine (bâches sur mesure) et aux grossistes de l’emballage et de l’isolation.

NOS AVANTAGES CONCURRENTIELS

Une très importante capacité de production en France : actuellement jusqu’à 20 millions de m2 de film par an !

Notre capacité à créer des formulations spécifiques (sur-mesure)

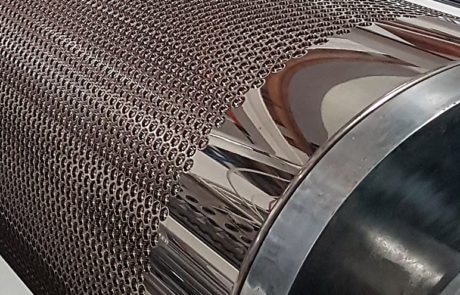

La création d’appareils de contrôles propres à notre métier pour un suivi de qualité